|

|

|

|

|

|

ON SALE NOW

Introducing the Polaris Lab Water Systems

High Purity Water Made In The USA.

Click here for more info. |

|

|

|

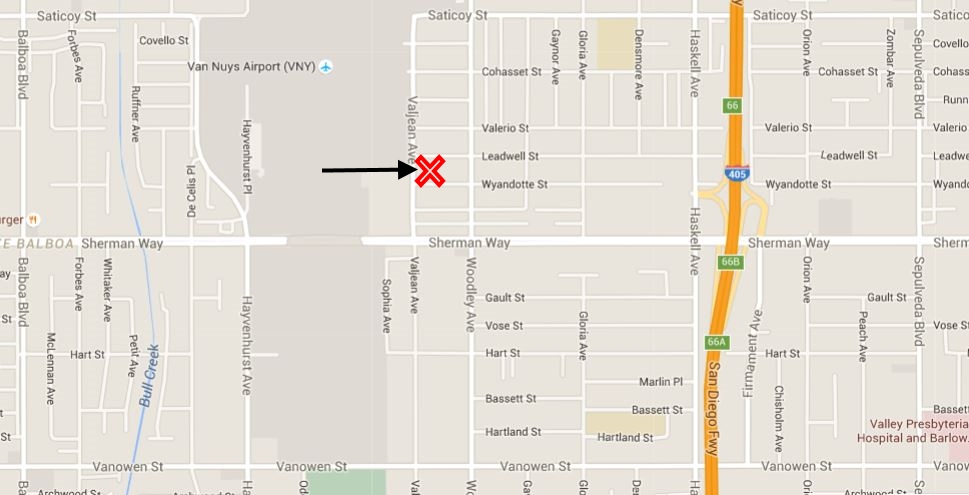

42150-AD

Commercial - Laboratory Water Distiller

Automatic Distiller - 42 gal./day

with 150 gallon storage tank and Auto Boiler Drain. Ships Via Truck Freight Only. We will quote extra costs upon request.

Commercial/Home Distiller Units.

Storage Tanks

Accessories

Retail Price :

$8,615.05

Our Low Price : $8,014.00

Bottled and Distilled

Myths and facts about distilled drinking water

About Distilled Water

Distillation is the single most effective method for producing purified water. The distiller can remove a greater range of pollutants to a higher degree than any other single apparatus. No process, natural or artificial, including filtration, deionization and reverse osmosis is so efficient.

For these reasons, distillation has long been recognized as a standard for purity and dependability. Most liquid prescription medicines are blended with distilled water to avoid problems with the inconsistent quality of water. Many doctors prescribe distilled water for their patients to drink, especially those on sodium or salt restriced diets.

Distillation normally removes 99.99% of the dissolved minerals in water. Carry-over is primarily a concern with volatile organic chemical contaminants. Filtering the distilled water through a carbon filter removes these contaminants. An activated post carbon filter is recommended for this purpose.

Most people know that water is an unreliable source of minerals. Furthermore, they are inorganic minerals that the body has difficulty absorbing. Mineral sources come from food we eat, not the water we drink. These mineral sources are organic and readily assimilated by the body for good health.

A distiller is most desirable for producting point-of-use drinking water for you than any other method of purification. They are durable, dependable and require a minimum of maintenance for continuous operation. With basic care, THEY WILL CONSISTENTLY PRODUCE HIGH QUALITY WATER for the life of the appliance and the quality WILL NOT DECLINE with use.

NO PROCESS IS AS EFFECTIVE OR RELIABLE AS DISTILLATION!

How Your Commercial Works:

In the distillation process, water in the boiling tank comes to a boil, creating steam.

The steam rises, leaving behind bacteria killed in the boiling process, as well as chemicals, heavy minerals and pollutants found in the water source.

The steam moves past a volatile gas vent, into the condenser coils where it is cooled by air and condenses to become pure distilled water.

Automatic Distiller - 42 gal./day

with 150 gallon storage tank

Height 17 inches

Width 23 inches

Depth 18 inches

Shipping Weight 36 lbs.

Produces 42 gallons approximately 160 liters every 24 hours.

Storage Tank

Holds 80 gallons

Height 52 inches

Diameter 30 inches

Overall Height 70 inches

Proven design with FLOAT CONTROL feature

316 alloy evaporator

Incoloy stainless steel heating element

Connects to water line for continuous automatic operation

Volatile gas vent system

Stainless steel support frame with casters

Built-in connection for adding remote faucet system to provide distilled water throughout the house

About Distilled Water

Bottled and Distilled

Laboratory Distillers

Residential and Commercial Distillers

Related Categories

|

See All : Stainless Steel Laboratory Water Distiller Packages |

|

|

All Images are representative and may or may not be of actual product.

Tags : HYDROPONIC WATER | 42150-AD | - | COMMERCIAL | - | LABORATORY | WATER | DISTILLER

HYDROPONIC-WATER.COM content

(C)2009-2024 APS Water Services Corporation - All rights reserved

Website Software - Multi-Website Content Manager - Wilson Web Engineering (C)2012-2024

Micro-Website is a trademark of Wilson Web Engineering

42150-ad - commercial - laboratory water distiller

hydroponic-water.com micro-website™

12/22/2024

3:13:27 PM

Google Apps

Google Apps

|